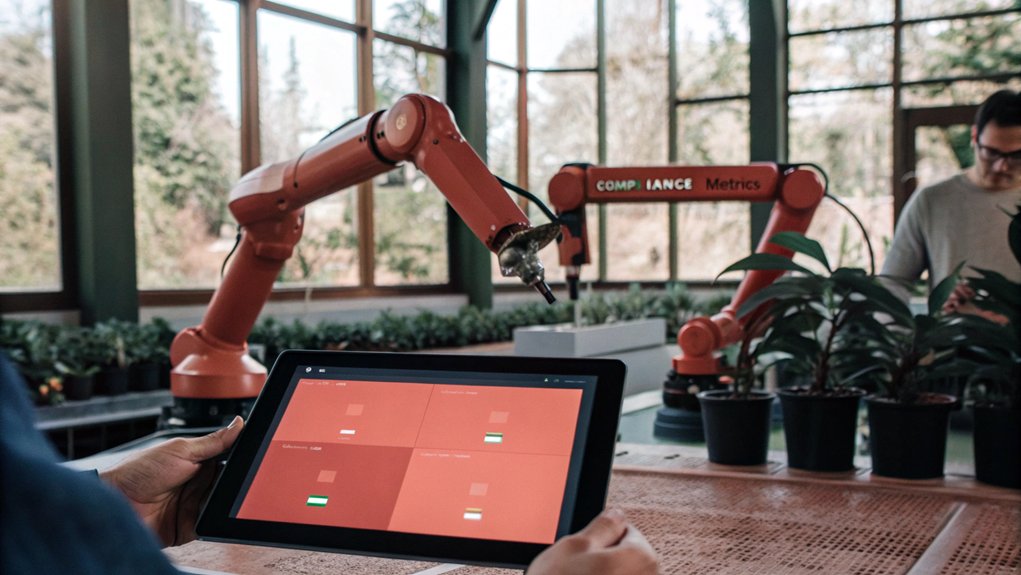

Sustainable & Compliance Solutions in Manufacturing

In today’s manufacturing landscape, balancing sustainability with compliance isn’t just a trend—it’s a necessity. As regulations tighten and consumer expectations shift, you must navigate complex challenges while optimizing resource use. By adopting strategic solutions, you can not only mitigate risks but also enhance your brand’s reputation. The integration of advanced technologies plays a pivotal role, prompting a closer look at how these innovations can transform your operations. What steps will you take to stay ahead?

Steering through the evolving regulatory requirements can be intimidating for you as a manufacturer, especially with the potential for significant penalties looming.

Achieving supply chain transparency while implementing effective risk mitigation strategies is essential to staying compliant and maintaining your competitive edge.

Steering through the evolving regulatory requirements can be intimidating for you as a manufacturer, especially with the potential for significant penalties looming.

Achieving supply chain transparency while implementing effective risk mitigation strategies is essential to staying compliant and maintaining your competitive edge.

Implementing compliance management solutions can greatly enhance your operational efficiency by streamlining processes and reducing errors.

By improving regulatory adherence, you not only minimize risks but also strengthen your brand’s trustworthiness among consumers demanding sustainable practices.

These benefits position your organization to thrive in an increasingly competitive market focused on ethical sourcing and transparency.

Implementing compliance management solutions can greatly enhance your operational efficiency by streamlining processes and reducing errors.

By improving regulatory adherence, you not only minimize risks but also strengthen your brand’s trustworthiness among consumers demanding sustainable practices.

These benefits position your organization to thrive in an increasingly competitive market focused on ethical sourcing and transparency.

Integrating sustainability into product development isn’t just a trend; it’s a strategic necessity that shapes the future of manufacturing.

By adopting a Design for Environment (DfE) approach, you can minimize environmental impact through thoughtful material selection and lifecycle considerations from the outset. Early-stage material management enables you to track substances of concern, calculate carbon footprints, and guarantee compliance with sustainability standards, paving the way for eco-friendly products.

Embracing a circular economy further enhances product design, encouraging reuse, recycling, and remanufacturing to greatly reduce waste.

As consumer demand for sustainable offerings grows—especially among Gen Z—prioritizing these strategies in your product development not only meets compliance but also aligns your brand with values that resonate deeply with your target audience.

Integrating sustainability into product development isn’t just a trend; it’s a strategic necessity that shapes the future of manufacturing.

By adopting a Design for Environment (DfE) approach, you can minimize environmental impact through thoughtful material selection and lifecycle considerations from the outset. Early-stage material management enables you to track substances of concern, calculate carbon footprints, and guarantee compliance with sustainability standards, paving the way for eco-friendly products.

Embracing a circular economy further enhances product design, encouraging reuse, recycling, and remanufacturing to greatly reduce waste.

As consumer demand for sustainable offerings grows—especially among Gen Z—prioritizing these strategies in your product development not only meets compliance but also aligns your brand with values that resonate deeply with your target audience.

As manufacturers increasingly prioritize sustainability, leveraging technology for enhanced compliance monitoring becomes essential in maneuvering complex regulatory landscapes.

By integrating IoT and sensors, you can achieve real-time monitoring of environmental compliance metrics, swiftly identifying potential non-compliance issues.

Utilizing big data analytics allows you to sift through vast regulatory information, pinpointing risk factors that can improve decision-making processes.

AI-driven predictive analytics further empowers you by forecasting potential non-compliance events based on historical trends, enabling proactive risk mitigation.

Additionally, blockchain technology enhances supply chain transparency, ensuring traceability of materials and adherence to ethical sourcing standards.

Finally, compliance management software centralizes regulatory data, automating tracking and streamlining your monitoring processes, ultimately reducing the burden on your compliance teams.

As manufacturers increasingly prioritize sustainability, leveraging technology for enhanced compliance monitoring becomes essential in maneuvering complex regulatory landscapes.

By integrating IoT and sensors, you can achieve real-time monitoring of environmental compliance metrics, swiftly identifying potential non-compliance issues.

Utilizing big data analytics allows you to sift through vast regulatory information, pinpointing risk factors that can improve decision-making processes.

AI-driven predictive analytics further empowers you by forecasting potential non-compliance events based on historical trends, enabling proactive risk mitigation.

Additionally, blockchain technology enhances supply chain transparency, ensuring traceability of materials and adherence to ethical sourcing standards.

Finally, compliance management software centralizes regulatory data, automating tracking and streamlining your monitoring processes, ultimately reducing the burden on your compliance teams.

To achieve regulatory compliance effectively, you need to implement a centralized compliance management system that offers real-time visibility across your operations.

This system, combined with proactive regulatory monitoring strategies, will substantially reduce the risk of non-compliance.

To achieve regulatory compliance effectively, you need to implement a centralized compliance management system that offers real-time visibility across your operations.

This system, combined with proactive regulatory monitoring strategies, will substantially reduce the risk of non-compliance.

As companies increasingly recognize the importance of sustainability in manufacturing, numerous success stories illustrate the tangible benefits of eco-friendly initiatives.

American Axle Holdings, Inc. enhanced their environmental stewardship by improving compliance management through Enhesa’s solutions, leading to operational efficiency and reduced waste.

Siemens USA implemented a robust safety compliance program that not only mitigated risks but also fostered a strong safety culture, resulting in lower incident rates.

Meanwhile, a multinational company navigated complex regulatory compliance challenges with Enhesa’s expertise, improving jurisdictional understanding.

These cases highlight how integrating sustainability initiatives can boost energy efficiency, reduce operational costs, and yield significant financial benefits, proving that adopting sustainable manufacturing practices fosters both compliance and competitive advantage.

As companies increasingly recognize the importance of sustainability in manufacturing, numerous success stories illustrate the tangible benefits of eco-friendly initiatives.

American Axle Holdings, Inc. enhanced their environmental stewardship by improving compliance management through Enhesa’s solutions, leading to operational efficiency and reduced waste.

Siemens USA implemented a robust safety compliance program that not only mitigated risks but also fostered a strong safety culture, resulting in lower incident rates.

Meanwhile, a multinational company navigated complex regulatory compliance challenges with Enhesa’s expertise, improving jurisdictional understanding.

These cases highlight how integrating sustainability initiatives can boost energy efficiency, reduce operational costs, and yield significant financial benefits, proving that adopting sustainable manufacturing practices fosters both compliance and competitive advantage.

Sustainable manufacturing success stories underscore the need for effective compliance strategies that can adapt to evolving regulatory landscapes.

Cross-functional teams play a pivotal role in compliance initiatives, weaving together diverse expertise across departments. They guarantee regulatory requirements are met while driving sustainability efforts.

Here’s how they contribute:

Sustainable manufacturing success stories underscore the need for effective compliance strategies that can adapt to evolving regulatory landscapes.

Cross-functional teams play a pivotal role in compliance initiatives, weaving together diverse expertise across departments. They guarantee regulatory requirements are met while driving sustainability efforts.

Here’s how they contribute:

A significant shift is underway in manufacturing as companies increasingly prioritize sustainability and compliance amid evolving regulations.

Advanced technologies like IoT and AI are enhancing real-time monitoring, allowing you to streamline manufacturing processes while reducing energy consumption.

With 73% of Gen Z consumers willing to pay more for eco-friendly products, integrating sustainability into your supply chain strategy isn’t just beneficial; it’s essential for market competitiveness.

A significant shift is underway in manufacturing as companies increasingly prioritize sustainability and compliance amid evolving regulations.

Advanced technologies like IoT and AI are enhancing real-time monitoring, allowing you to streamline manufacturing processes while reducing energy consumption.

With 73% of Gen Z consumers willing to pay more for eco-friendly products, integrating sustainability into your supply chain strategy isn’t just beneficial; it’s essential for market competitiveness.

Maneuvering the complexities of compliance and sustainability in manufacturing can be intimidating, yet Enhesa offers tailored solutions that simplify this process for you.

Their expertise allows you to navigate evolving regulations while enhancing your sustainability efforts.

Maneuvering the complexities of compliance and sustainability in manufacturing can be intimidating, yet Enhesa offers tailored solutions that simplify this process for you.

Their expertise allows you to navigate evolving regulations while enhancing your sustainability efforts.

Key Takeaways

- Implementing compliance management solutions streamlines processes, enhances operational efficiency, and reduces errors in sustainable manufacturing practices.

- Utilizing advanced technologies like IoT and AI provides real-time monitoring and predictive analytics for improved regulatory compliance.

- Embracing a circular economy through reuse and recycling minimizes waste and aligns with sustainability goals.

- Centralized compliance systems ensure visibility across operations, facilitating proactive regulatory monitoring and risk management.

- Regular internal audits and employee training promote awareness of compliance standards and identify potential gaps in sustainability efforts.

Understanding the Importance of Sustainability in Manufacturing

As you explore the domain of manufacturing, understanding the importance of sustainability is essential for not only meeting regulatory demands but also enhancing your competitive edge. Embracing sustainable manufacturing practices minimizes negative environmental impacts while optimizing resource efficiency. Compliance with environmental regulations like the Paris Agreement is critical to avoid significant penalties and reputational harm.Embracing sustainable practices reduces environmental harm and enhances resource efficiency while ensuring compliance with vital regulations.Furthermore, integrating renewable energy into your operations boosts operational efficiency and cuts costs. With 73% of Gen Z consumers willing to pay more for sustainable products, prioritizing sustainability cultivates customer loyalty and positions your brand favorably in the market. Ultimately, adopting these practices not only fulfills compliance but also drives long-term business benefits, paving the way for a resilient and responsible manufacturing future.

Key Compliance Challenges Faced by Manufacturers

Evolving Regulatory Requirements

While manufacturers endeavor to enhance sustainability practices, they’re increasingly confronted with complex regulatory requirements that demand vigilant compliance efforts. Manufacturers need to navigate evolving global standards, like the EU’s REACH regulation and the Clean Air Act in the USA, which impose stringent reporting and emissions limits. Achieving regulatory compliance isn’t just about avoiding fines; it’s about demonstrating commitment to sustainability goals through robust environmental management systems. Adopting ISO 14001 standards can greatly improve compliance management and environmental performance. To mitigate risks, manufacturers must embrace proactive compliance strategies, such as implementing real-time monitoring systems and conducting regular audits.Supply Chain Transparency

Supply chain transparency has become essential for manufacturers aiming to meet increasing regulatory demands and sustainability goals. You must navigate compliance requirements like the EU’s REACH and the US’s Toxic Substances Control Act, which necessitate strict reporting on hazardous materials. Without visibility into sub-tier suppliers, you face significant compliance risks, as over 70% of disruptions stem from these less visible levels. Research shows that companies with high supply chain transparency are 2.5 times more likely to comply with environmental regulations and maintain customer trust. Leveraging technology solutions like blockchain allows you to track materials and guarantee ethical sourcing, effectively addressing compliance challenges related to labor practices and environmental standards while fostering sustainable practices throughout your supply chain.Risk Mitigation Strategies

As manufacturers grapple with the complexities of compliance, they must implement effective risk mitigation strategies to safeguard against financial penalties and operational disruptions. Centralizing compliance standards and leveraging sustainability intelligence can streamline processes, reducing supply chain risks linked to regulatory compliance. Maintaining active legal registers and efficiently tracking regulatory changes guarantees you stay ahead of evolving requirements. Additionally, proactive internal audits and ongoing training are essential for verifying compliance and identifying gaps in your strategies. By harnessing advanced technologies like IoT and AI, you can enhance real-time monitoring and predictive analytics, considerably diminishing the likelihood of compliance violations. Embracing these strategies fosters a resilient manufacturing environment that prioritizes compliance and sustainability.Benefits of Implementing Compliance Management Solutions

Enhanced Operational Efficiency

While maneuvering through the complexities of modern manufacturing, adopting compliance management solutions can greatly enhance your operational efficiency. By centralizing compliance standards and leveraging sustainability intelligence, you can reduce redundancy and streamline processes across your facilities. This improved accuracy in environmental compliance reporting mitigates risks associated with non-compliance penalties. A proactive compliance approach fosters continuous improvement, helping you identify and resolve inefficiencies early. Furthermore, these solutions promote collaboration among cross-domain teams, facilitating informed decision-making that enhances product quality while upholding sustainability standards. Utilizing advanced technologies like IoT and big data analytics enables real-time monitoring and predictive insights, optimizing your resource use and ultimately reducing operational costs. This strategic shift not only boosts efficiency but also aligns with your sustainability goals.Improved Regulatory Adherence

To enhance regulatory adherence, manufacturers must leverage compliance management solutions that provide centralized access to the latest legal registers and efficiently track regulatory changes. These solutions enable improved regulatory adherence by keeping you informed about critical regulatory requirements, ultimately minimizing negative environmental impacts. By implementing compliance management software, you not only reduce risks associated with non-compliance but also foster the development of sustainable products that exceed corporate standards. This proactive approach to risk management allows you to anticipate future regulations, ensuring your manufacturing operations remain aligned with environmental compliance and sustainability initiatives. In addition, integrating these solutions promotes transparency and collaboration among teams, creating a cohesive environment committed to regulatory excellence and shared responsibility.Increased Brand Trustworthiness

A strong compliance management system not only streamlines regulatory adherence but also plays a pivotal role in enhancing brand trustworthiness. By prioritizing sustainability and compliance, you establish transparency that resonates with consumers. With 73% of Gen Z willing to pay a premium for sustainable products, your commitment to ethical sourcing fosters brand loyalty and strengthens your market position. Effective compliance management demonstrates corporate responsibility, building trust with stakeholders and investors who are increasingly focused on sustainability. Regular monitoring and reporting offer credible evidence of your dedication to sustainable practices, making your brand more appealing in a competitive marketplace. Ultimately, a robust compliance framework not only mitigates risks but also enhances your reputation, aligning with consumer demand for sustainable solutions.Integrating Sustainability Into Product Development

Leveraging Technology for Enhanced Compliance Monitoring

Strategies for Achieving Regulatory Compliance

Centralized Compliance Management Systems

Centralized compliance management systems offer a strategic advantage for manufacturers working to meet regulatory standards efficiently. By unifying compliance tracking across multiple facilities, you reduce redundancy and enhance operational efficiency. These systems provide real-time monitoring of regulatory changes, allowing you to maintain active legal registers and swiftly adapt to new requirements, thereby mitigating compliance challenges. Integrating sustainability intelligence enables you to manage environmental standards effectively, ensuring adherence to global frameworks. Furthermore, these systems promote collaboration among your teams, fostering cross-domain visibility and informed decision-making. Ultimately, implementing a centralized compliance management system can lead to significant cost savings by minimizing operational disruptions and reducing penalties, enhancing your overall compliance management efficiency.Proactive Regulatory Monitoring Strategies

While many manufacturers react to regulatory changes as they arise, adopting proactive regulatory monitoring strategies can greatly enhance compliance efforts and operational resilience. By implementing centralized compliance systems, you can maintain active legal registers that provide real-time updates on regulatory changes. Leveraging advanced technologies like IoT and big data analytics helps you identify compliance risks early, allowing for swift adaptability. Consider these strategies:- Conduct regular internal audits to spot compliance gaps

- Offer training programs to keep employees informed

- Foster collaboration across teams to streamline processes

- Integrate sustainability standards throughout the product lifecycle

- Utilize data analytics for informed decision-making

Case Studies: Success Stories in Sustainable Manufacturing

The Role of Cross-Functional Teams in Compliance Initiatives

- Foster innovation in product design for environmentally safe solutions

- Enhance operational efficiency by centralizing compliance standards

- Promote effective communication for timely updates on regulatory changes

- Create a proactive culture of risk management throughout the organization

- Streamline processes to eliminate redundancy and improve productivity

Future Trends in Sustainability and Compliance in Manufacturing

Integrating sustainability into your supply chain is crucial, as 73% of Gen Z consumers prioritize eco-friendly products.Regulatory frameworks are tightening, with initiatives like the EU Green Deal pushing you to adopt proactive compliance measures. The expected growth of sustainable manufacturing technologies, projected to reach $7.3 trillion by 2030, highlights the importance of circular supply chains and corporate responsibility initiatives in fostering a future where sustainability drives competitive advantage.

How Enhesa Supports Manufacturers in Compliance and Sustainability Efforts

- Centralized compliance standards for streamlined processes

- Active legal registers to track regulatory changes

- Guidance on environmentally safe product lifecycle management

- Mitigation of supply chain risks

- Continuous improvement in waste management practices